OZONE For Beef Processing & SANITATION

Ozone is the perfect solution for the Beef Processing Industry, for plant cleaning, disinfecting, and sanitizing. The following data and images offer clear facts to the benefits of ozone. No doubt you have seen information about the attributes of ozone being an effective agent of against Listeria, E-Coli, Salmonella, Hepatitis, Cholera, and other bacteria and pathogens.

Other articles noted USDA -- FDA acceptance in June 2001; Inherent risks of the traditionally used chlorine chemical gas; and several incidents involving recent Listeria recalls..

Ozone Technology in the Beef Industry:

In 2001, The Food and Drug Administration published a final ruling in the federal register accepting ozone as an additive to kill food borne pathogens.

The FDA ruling allows for the use of ozone in the processing of all foods, including meat and poultry.

The Food and Drug Administration amended its food additive regulations to permit ozone use as an anti-microbial agent.

Published in the Federal Register, the final rule allows for ozone use in gaseous and aqueous phases, and for the anti-microbial treatment of meat and poultry.

The amendment resulted from a petition, and date provided by the Electric Power Research Institute and the Agriculture and Food Technology Alliance.

A large number of processors are using ozone in their meat processing plants.

Other articles noted USDA -- FDA acceptance in June 2001; Inherent risks of the traditionally used chlorine chemical gas; and several incidents involving recent Listeria recalls..

Ozone Technology in the Beef Industry:

In 2001, The Food and Drug Administration published a final ruling in the federal register accepting ozone as an additive to kill food borne pathogens.

The FDA ruling allows for the use of ozone in the processing of all foods, including meat and poultry.

The Food and Drug Administration amended its food additive regulations to permit ozone use as an anti-microbial agent.

Published in the Federal Register, the final rule allows for ozone use in gaseous and aqueous phases, and for the anti-microbial treatment of meat and poultry.

The amendment resulted from a petition, and date provided by the Electric Power Research Institute and the Agriculture and Food Technology Alliance.

A large number of processors are using ozone in their meat processing plants.

Ozone is Proven Effective.

"Ozone is the most effective antimicrobial agent known. It kills E-coli 3,125 times faster than chlorine, and it converts into ordinary oxygen after the process, leaving no chemical residuals behind."

Ozone technology offers many advantages. Its efficiency at ambient temperatures is as great as ultra-hot water. And water treated with ozone can be effectively reused requiring limited filtration. Ozonated water can be used anywhere in a packing or processing plant.

Anywhere you're running water through pipes, you can use low-level ozonated water. You can use higher levels of ozonated water in cleaning off equipment, conveyor belts, hooks, and those sorts of things-in addition to actually coming into contact with a food product.

Companies are also using our Ozone Air Clean Systems. These systems provide low-level ozone which can be used in a gaseous form to help control mold, fungus, bacterial growth and mildew in areas like cold storage and holding rooms.

Ozone destroys pathogens by attacking and oxidizing the cell walls of the organism; the mucous membranes.

It doesn't matter whether they are gram-positive or gram-negative. Whether they are spores, whether they are active, or whether they are amoeba-types (or microorganisms). The pathogens are all comprised of double-carbon bonds to hold the molecular structure together, and any microorganisms exposed to ozone will not just become benign in the water, but instead it will be completely evaporated. That's because ozone will continue to break that molecular chain down until it's nothing but carbon dioxide and water. Ozone is approved and showing great results for sanitizing equipment and disinfecting food product for beef processors.

"Ozone is the most effective antimicrobial agent known. It kills E-coli 3,125 times faster than chlorine, and it converts into ordinary oxygen after the process, leaving no chemical residuals behind."

Ozone technology offers many advantages. Its efficiency at ambient temperatures is as great as ultra-hot water. And water treated with ozone can be effectively reused requiring limited filtration. Ozonated water can be used anywhere in a packing or processing plant.

Anywhere you're running water through pipes, you can use low-level ozonated water. You can use higher levels of ozonated water in cleaning off equipment, conveyor belts, hooks, and those sorts of things-in addition to actually coming into contact with a food product.

Companies are also using our Ozone Air Clean Systems. These systems provide low-level ozone which can be used in a gaseous form to help control mold, fungus, bacterial growth and mildew in areas like cold storage and holding rooms.

Ozone destroys pathogens by attacking and oxidizing the cell walls of the organism; the mucous membranes.

It doesn't matter whether they are gram-positive or gram-negative. Whether they are spores, whether they are active, or whether they are amoeba-types (or microorganisms). The pathogens are all comprised of double-carbon bonds to hold the molecular structure together, and any microorganisms exposed to ozone will not just become benign in the water, but instead it will be completely evaporated. That's because ozone will continue to break that molecular chain down until it's nothing but carbon dioxide and water. Ozone is approved and showing great results for sanitizing equipment and disinfecting food product for beef processors.

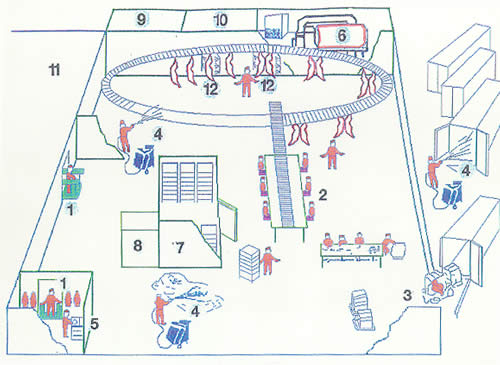

12 Ways to Improve your Beef Processing Plant Using Ozone

- Hand and Boot walk through ozone sanitizer

- Ozone Hand Spray Stations, for sanitizing hand, gloves and knives

- Fork Lift Wheel sanitizer with ozone

- Ozone Mobile Sanitizer for plant sanitation

- Hand and Arm Washing System using E-2 Anti-Microbial Soap or Ozone Sanitizing

- Aqua-Clean Waste Treatment System

- Ozone Air Clean Wall-mounted in Cooler

- Ozone Recycle sanitizer glycol tank

- Zero-Discharge recycle cooling tower System

- Well water treated with Aqua-Clean ozone Sanitizer

- Effluence from Holding Pen, sanitized before discharging to sewer drains

- Sanitizing carcasses with ozone spray